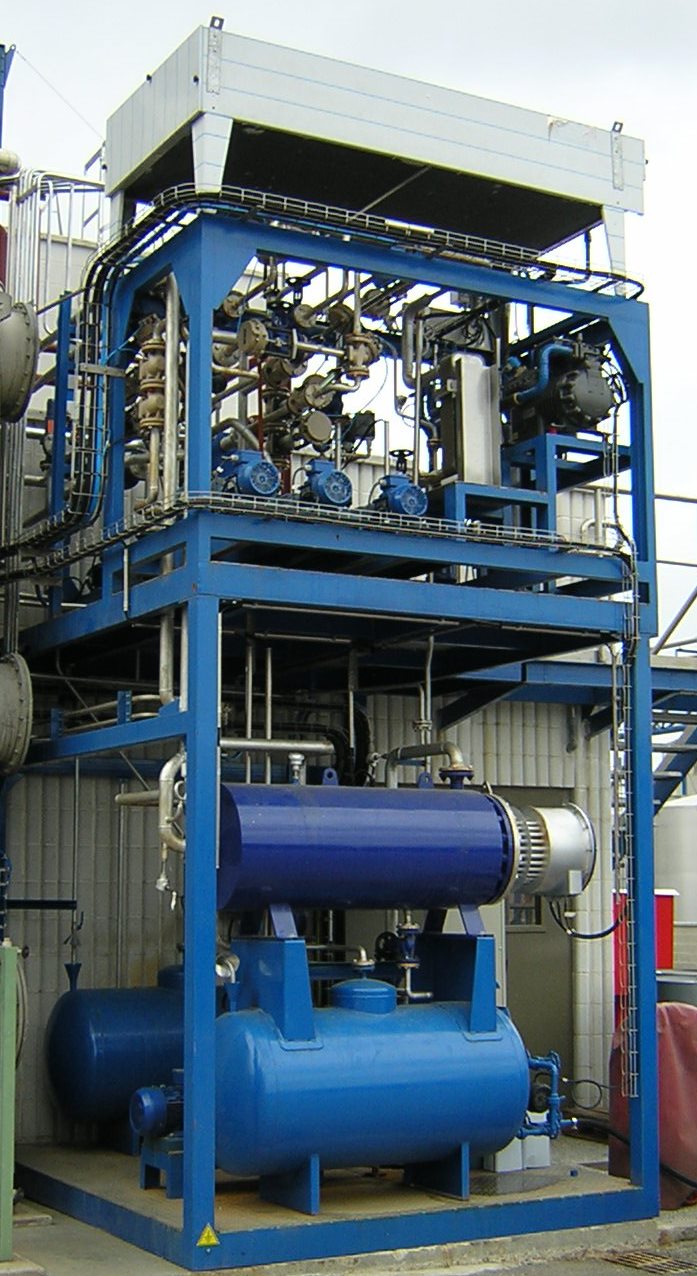

Monofluid System

- Working temperature +360ºC/-70ºC

- Leading technology

- Excellent quick response

- Accuracy and repeatability time / temperature

- Without brine

- No corrosion

- Efficient heat transfer

- No temperature discontinuity

- Safety

- High reliability

- Energy saving

- Suitable for cryogenic systems

- Specific monobloc designs

Monofluid System heating/cooling +360ºC/-70ºC

With operations in batch it is usual to alternate heating and cooling processes on single equipment, such as a reactor.

The traditional system is through the use of multiple fluids (steam, water, brine, ...) but due to the different characteristics of the fluids and the very different transmission coefficients it is difficult to control the process.

Description:

A single thermal fluid (monofluid) flows through the half pipe coil or outer wall of the equipment.

There are several primary circuits of monofluid at different temperatures (hot, medium, cold, very cold ...) which are circulating continuously and are kept at a constant temperature. For each consumer there is a separated secondary circuit, with a circulation pump that ensures a constant flow of monofluid. The monofluid temperature in the secondary circuit can be modified continuously. The control system, depending on the heating/cooling needs will allow the entrance and will modulate the input of monofluid from each one of the primary circuits.

Gradual increase or decrease in temperature:

- No discontinuities or downtime due to the changes of fluids.

- Provides excellent protection against thermal shock in glass-lined reactors.

- Avoids secondary reactions and run-away.

- Without interrupting the process and no hot spots.

- Higher productivity and quality.