3.

Biomass heater

- Fuel saving by substitution of fossil fuels

- Leading technology

- Low energy consumption

- High reliability

- Large heating surface

- Specific designs for each type of fuel

- Emissions treatment

- Telemanagement

Biomass heaters:

- Thermal fluid

- Hot water

- Superheated water

Thermal energy can be obtained from by-products that the industry itself generates which can be used as fuel, with the consequent saving of fuels derived from petroleum.

Types of combustion chambers:

Depending on the available biomass (source, moisture, composition, grain size, ...):

- Prefabricated, monobloc, vertical or horizontal cylindrical.

- Underground systems:

- Fixed inclined grids

- Mobile grids

Characteristics:

- Standards for design, construction and maintenance UNE 9-310, DIN 4754, VDI 3033

-

Marking Directive 97/23/CE DEP

Marking Directive 97/23/CE DEP - Indirect Surveillance with intervals of 24 hours supervision (or 72 hours optional)

- High velocity and turbulence of the thermal oil

- High heat transfer surface

- Low thermal load

- Oversized combustion chamber

- Vertical construction

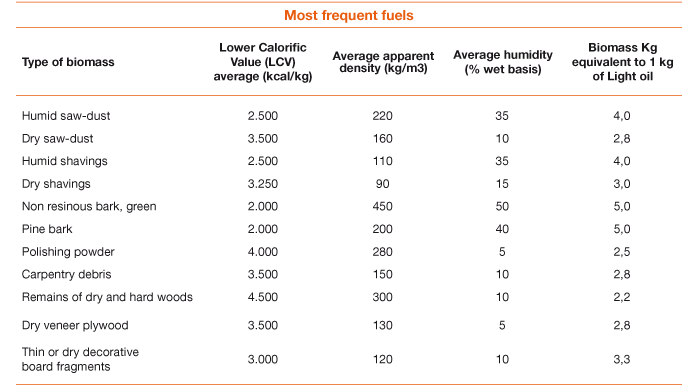

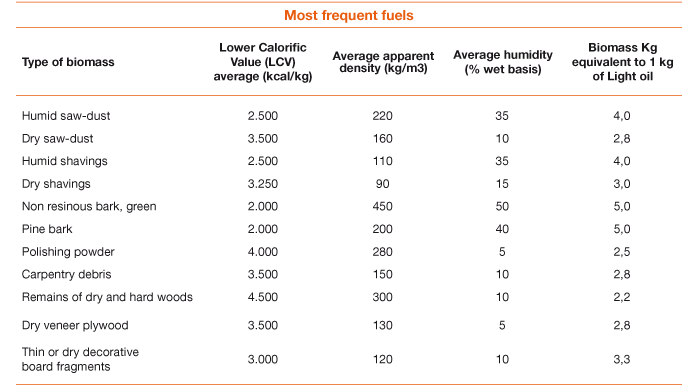

Fuel: sawdust and shavings, veneer, bark, sanding dust, carpentry debris......

Complete systems:

- Silos for fuel storage and heater feeding.

- Multicyclonic separators with high efficiency.

- Economizers

- Automatic feeding

- Automatic cleaning of ashes

- Rotary valves special for high temperature for discharge of unburned